LINK

Upholstery Staple Gun

ON-SITE RESEARCH

Orange Chair Upholstery

For the first step in our research, our group traveled to Orange Chair, an upholstery company located in downtown, Cincinnati. There we met Danielle, who showed us around the shop and how the company operates.

Process

We learned that all designs start in Rhino and get milled out. From there they are assembled with mostly a wide array of staple guns and are then sent over to get padded and upholstered. The most often used staple gun was the 22 gauge upholstery staple gun.

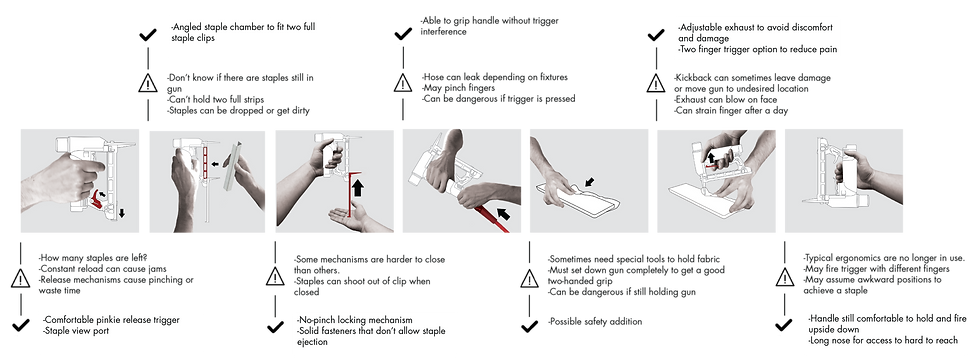

TASK ANALYSIS

MARKET OPPORTUNITY GAP

Market Opportunity Gap

A 22 gauge upholstery staple gun is missing from Makita’s current line of pneumatic staple guns. Most of the large competitors also don’t have an upholstery staple gun.

COMPETITION MATRIX

Competition Matrix

It is interesting to see that the cheaper products generally have better reviews. This might be because of reduced expectations and a lack of design improvement in the higher models. Senco is the main competitor in that space.

BRAND ANALYSIS

LXT Sub-Compact VBL

-Sub-Compact is a new class within the LXT line of Makita tools. The Sub-Compact class focuses on a compact and lightweight feel with all the power of a larger tool. The logo pocket remains the same as the traditional Makita logo pocket. The LXT Sub-Compact line is a blackout colorway with white accents.

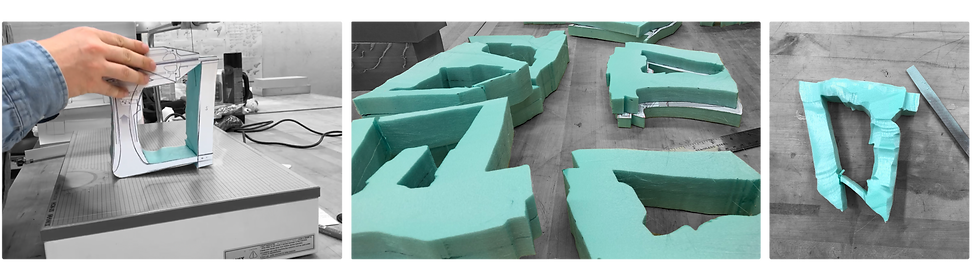

FOAM EXPLORATION

IDEATION

FOAM MODEL IDEATION PROCESS

FINAL CONCEPT

Addressed Product Goals

- Improved comfort of Trigger mechanisms

- Adjusted staple chamber for higher convenience and efficiency.

- Adjustable exhaust system.

- Ergonomic considerations in multiple orientations.

FOAM MODELS

3D Printing

CAD models were created of the handle of the staple gun. 3D printing was used as a preliminary method to create an ergonomic prototype.

CNC Machining

Once a general form was created, CNC machining was used to create precise prototypes for small adjustments.

.png)

Milling Pattern

PROTOTYPING

CNC MILLING

A CNC machine was used to create a precise main form out of REN foam.

RESIN PRINTING

Some of the parts were created using 3D resin printing. This method allowed for precise printing at a smaller scale.

FINISHING

The parts were all sanded and coated with many coats of an alcohol-based primer. That primer was then sanded and polished. All the parts were then glued together.

Staple Viewing Window

Two Finger Trigger

Quick Reload Trigger

Textured Grip

Adjustable Airflow

Air Exhaust

Easily Removed Cover For Repair

Quick Connect Hose Coupling

Angled Staple Chamber

Easy Fix Clogged Chamber

Rubber Bumpers